Divided Designs

It is possible to independently

design two fabrics and then

combine their threadings, tie-ups,

treadlings (or peg plans) into a

single design and weave them as

a single fabric on a single loom.

The resulting weave structure

will, under certain circumstances,

retain some properties of

the original ones, and new (and

unusual) features are also likely

to appear.

This technique of combining two

separately-designed fabrics is

called a “divided design.”

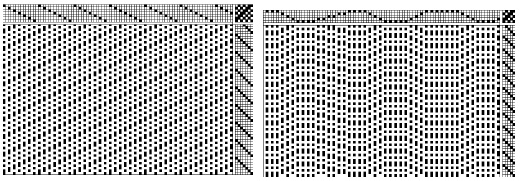

The two designs at the bottom of

this page illustrate two such

separate fabrics. Note that each

design omits every other thread, a

convenience when subsequently

merging the designs. The fabric

on the left uses seven harnesses

while the one on the right uses

five harnesses.

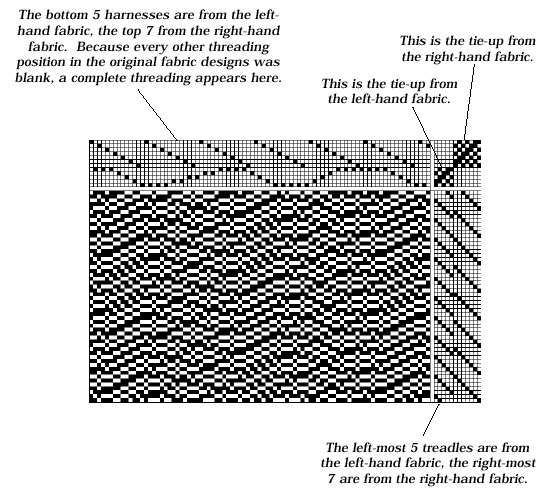

The two designs are merged into

a single design by alternating

the threadings, putting the tie-ups

corner-to-corner, and using

the treadlings side-by-side. The

figure on the facing page shows

the resulting design.

Divided design fabrics can have

long floats once the merger is

completed. Use WeaveMaker’s

full-fabric float analysis tools to

detect and correct this problem.

Because the final fabric has to

be woven on a loom which has

as many harnesses as the sum

of the harnesses for the original

fabrics, creating interesting final

fabrics tends to require a high

harness count.

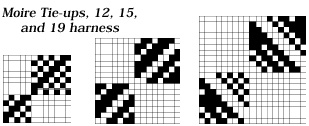

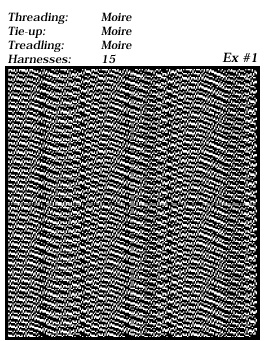

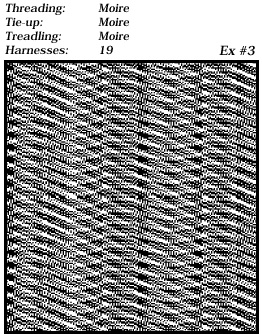

Moire Scheme

WeaveMaker has coordinated

threading, tie-up, and treadling

schemes, under the name Moire,

which create a divided design

fabric design (see the previous

page for a definition of “divided

design”).

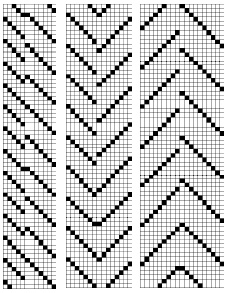

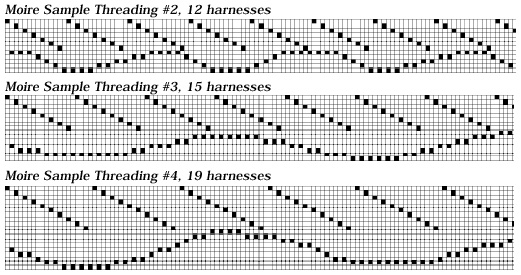

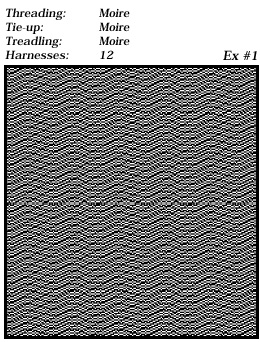

Weaving elements appear here

for 12, 15, and 19 harnesses

(treadlings at right, tie-ups and

threadings below), and sample

fabrics created from them appear

below.